Price 80 आईएनआर/ Kilograms

MOQ : 1 Pack

Specification

- ब्रश शेप

- उपयोग करें

- Industrial

- फंक्शन

- DC Motor

- उपयोग

- Industrial

- साइज

- As per client

- प्रॉडक्ट टाइप

- Alternator Carbon Brush

- वज़न

- ग्राम (g)

Trade Information

- Minimum Order Quantity

- 1 Pack

- आपूर्ति की क्षमता

- प्रति दिन

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

About

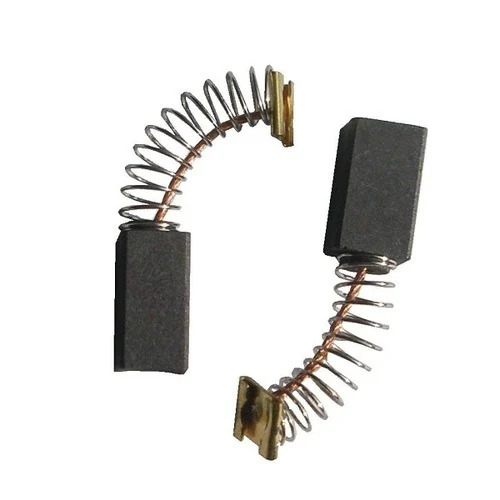

Introducing the acclaimed Alternator Carbon Brush & DC Motor Carbon Brush, a must-have solution for your industrial needs. Crafted by a peerless manufacturer, distributor, and supplier in India, these invincible brushes are designed to deliver masterful performance in demanding environments. Each brush is precisely engineered to client-specified sizes and features a cylindrical shape, optimally designed for robust DC motor functionality. At a weight of 500 grams, these brushes ensure reliable and long-lasting operation. Grab yours today for unmatched efficiency and durability in industrial applications!

Exceptional Application & Features for Industry

The Alternator Carbon Brush & DC Motor Carbon Brush is expertly used in a variety of industrial machines, particularly for DC motors. Notable features include a sturdy cylindrical shape, robust material composition, and seamless adaptability to customized size requests. Its use type is strictly industrial, making it an essential component for manufacturing, assembly lines, and heavy machinery operations. Rely on these premium brushes to maintain uninterrupted machine performance and operational excellence.

Reliable Supply, Swift Shipment, and Sample Availability

Order processing for the Alternator Carbon Brush & DC Motor Carbon Brush is streamlined to ensure rapid shipment and timely order completion. With impressive supply ability, bulk and custom orders are accommodated efficiently. Products are shipped via reliable FOB ports, maintaining the quality and condition of each shipment. Samples are available for evaluation, allowing clients to experience peerless quality before full-scale ordering. Our dedicated team ensures clear communication and smooth logistics throughout your purchasing experience.

Exceptional Application & Features for Industry

The Alternator Carbon Brush & DC Motor Carbon Brush is expertly used in a variety of industrial machines, particularly for DC motors. Notable features include a sturdy cylindrical shape, robust material composition, and seamless adaptability to customized size requests. Its use type is strictly industrial, making it an essential component for manufacturing, assembly lines, and heavy machinery operations. Rely on these premium brushes to maintain uninterrupted machine performance and operational excellence.

Reliable Supply, Swift Shipment, and Sample Availability

Order processing for the Alternator Carbon Brush & DC Motor Carbon Brush is streamlined to ensure rapid shipment and timely order completion. With impressive supply ability, bulk and custom orders are accommodated efficiently. Products are shipped via reliable FOB ports, maintaining the quality and condition of each shipment. Samples are available for evaluation, allowing clients to experience peerless quality before full-scale ordering. Our dedicated team ensures clear communication and smooth logistics throughout your purchasing experience.

FAQs of Alternator Carbon Brush & DC Motor Carbon Brush:

Q: How are the Alternator Carbon Brush & DC Motor Carbon Brush used in industrial applications?

A: These carbon brushes are specifically designed for DC motors and alternators in a range of industrial machinery. They ensure continuous electrical contact, minimizing downtime and enhancing the overall performance of the equipment.Q: What benefits do these carbon brushes offer over generic alternatives?

A: They provide masterful durability, improved conductivity, and longer operational life compared to generic brushes. Manufactured with high-grade materials and tailored to client specifications, they deliver invincible reliability in demanding conditions.Q: Where are these carbon brushes manufactured and supplied from?

A: They are manufactured and supplied by a reputable company based in India, serving as a manufacturer, distributor, supplier, trader, and service provider for industrial clients across the nation and internationally.Q: What is the process for ordering samples or bulk quantities?

A: You can request samples for evaluation before committing to a larger order. Once your requirements are received, the order is processed efficiently, with shipment and completion handled by our experienced logistics team.Q: When should industrial operators consider replacing their carbon brushes?

A: Operators should replace carbon brushes during routine maintenance checks or if noticeable wear, sparking, or reduced motor performance occurs. Timely replacement ensures consistent machinery efficiency.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें