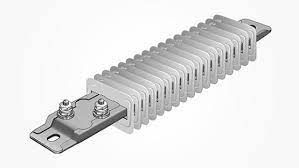

Industrial Strip Type Heaters

Industrial Strip Type Heaters Specification

- Usage & Applications

- Ideal for heating surfaces, machinery parts, tanks, molds, and dies in various industrial processes

- Type

- Other

- Material

- Stainless Steel

- Capacity

- Standard and Custom capacities available

- Voltage

- 220 V / 240 V

- Power

- 500 W - 3 kW (customizable)

- Power Source

- Electric

- Input Voltage

- 220 V / 240 V

- Output Voltage

- Output according to application requirements

- Installation Type

- Surface Mounted

- Dimension (L*W*H)

- Varies by model: Standard sizes from 300 mm x 25 mm x 10 mm upwards

- Weight (kg)

- Approx. 0.5 - 2 kg (depending on size)

- Color

- Metallic Silver

- Terminal Type

- Screw Terminal

- Corrosion Resistance

- Excellent resistivity due to stainless steel construction

- Heating Element

- Nickel-Chromium resistance wire

- Mounting Provision

- Factory provided holes for easy installation

- Insulation

- Ceramic/Mica insulation

- Thermal Efficiency

- High uniform heating efficiency

- Sheath Material

- Stainless Steel or Zinc coated steel

- Shape

- Flat/Rectangular

- Max Operating Temperature

- Up to 300°C

- Custom Options

- Available in custom lengths, wattages, and fittings

Industrial Strip Type Heaters Trade Information

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Industrial Strip Type Heaters

We are an affluent manufacturer and exporter of Industrial Strip Type Heaters that are widely used for various industrial applications. These are highly appreciated by clients for their robust design, high heating capacity and low power consumption. In order to design these, we make use of good quality metal alloy and other allied materials keeping in mind the set industry standards. Our Industrial Strip Type Heaters are tested thoroughly by our quality controllers in order to ensure their flawlessness.

Product details

|

Brand |

Customized |

|

Capacity |

As Per Requirement |

|

Weight |

Customized |

|

Product Type |

Heater |

|

Shape |

Scale Type , Straight, Strips |

|

Temperature |

up to 649 Deg C |

|

Size |

As Per Requirement |

|

Heater Material |

Stainless Steel |

|

Voltage |

12v to 440 v |

|

Power |

Electric |

Exceptional Performance & Durability

Equipped with high-quality Nickel-Chromium resistance wire and stainless steel construction, these strip heaters promise superior thermal efficiency and outstanding corrosion resistance. Their robust build enables long-term operation even in challenging industrial settings, ensuring maximum performance for diverse heating applications.

Flexible Customization Options

Industrial Strip Type Heaters support customization in length, wattage, fittings, and mounting provisions. This allows users to select the ideal configuration for their specific equipment or operational needs. Whether standard or unique specifications are required, tailored solutions can be easily accommodated.

Wide Range of Applications

These heaters are suitable for heating surfaces, molds, dies, and machinery components in various sectorsranging from manufacturing to processing industries. Their reliable performance and adaptability make them valuable for tasks demanding steady, uniform heat.

FAQs of Industrial Strip Type Heaters:

Q: How are Industrial Strip Type Heaters installed?

A: Industrial Strip Type Heaters feature factory-provided mounting holes, making them easy to surface-mount onto machinery parts, tanks, molds, or dies. Screw terminals further facilitate straightforward electrical connections.Q: What materials are used in the construction of these heaters?

A: These heaters are made with a Nickel-Chromium resistance wire for heating and stainless steel or zinc-coated steel as the sheath material. This combination ensures high thermal efficiency and excellent corrosion resistance.Q: When should I consider using a strip type heater for my application?

A: Strip type heaters are recommended when you need uniform surface heating for processes such as heating machinery parts, molds, tanks, or dies, especially in industrial environments requiring robust and efficient temperature control.Q: Where can custom-sized industrial strip heaters be used?

A: Custom-sized strip heaters can be applied to specialized machinery, custom-sized tanks, or unique industrial components, offering tailored heating solutions for both standard and non-standard requirements.Q: What benefits do stainless steel strip heaters offer over alternatives?

A: Stainless steel strip heaters provide exceptional resistance to corrosion, high thermal efficiency, uniform heating, and long service life, making them suitable for demanding, high-temperature industrial processes.Q: How does the customization process work for these heaters?

A: Customers can specify required lengths, wattages, voltage, and mounting options to match their exact application needs. Manufacturers or distributors will then design and fabricate heaters following those specifications.Q: What industries commonly use these strip heaters?

A: Industries such as manufacturing, plastics, food processing, chemical processing, and die/mold making frequently utilize strip type heaters for their reliable and efficient surface heating capabilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free