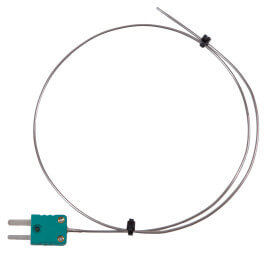

Mineral Insulated Thermocouple

Mineral Insulated Thermocouple Specification

- Cable Length

- Available from 1 meter to custom lengths

- Response Time

- Fast (typically 3 seconds, sheath dependent)

- Mounting Type

- Probe/Immersion, Surface, or Custom Mount

- Interface

- Direct connection to temperature measuring instruments, controllers, or transmitters

- Wireless

- No

- Sensor Type

- Mineral Insulated (MI) Thermocouple

- Sensitivity

- Approx. 41 V/C (Type K at 25C)

- Power Consumption

- Passive Device No Power Required

- Product Type

- Thermocouple Wire

- Input

- Temperature (Thermal Energy)

- Function

- Temperature Measurement and Monitoring

- Usage

- Industrial Temperature Sensing

- Accuracy

- Class 1, up to 1.5C or specified by thermocouple type

- Resolution

- 0.1C (dependent on instrumentation)

- Weight

- Varies (typically lightweight, depends on cable and sheath length/diameter)

- Standards Compliance

- IEC 60584, ASTM E230/E230M

- Sheath Material

- SS304, SS316, Inconel 600, as per requirement

- Minimum Bend Radius

- 2x sheath diameter

- Sheath Diameter

- Typically 1.0 to 8.0 mm (custom sizes available)

- Junction Type

- Grounded, Ungrounded, Exposed

- Insulation Resistance

- > 1000 M at 500V DC (at room temp)

- Thermocouple Types Available

- K, J, T, E, N (others on request)

Mineral Insulated Thermocouple Trade Information

- Main Domestic Market

- All India

About Mineral Insulated Thermocouple

Fostered with a team of highly experienced professionals, we are able to manufacture and export a broad assortment of Mineral Insulated Thermocouple. Available in different designs and shapes, the offered product is manufactured using superior grade raw materials and latest technology. Widely renowned for its beautiful design, durable finish, accurate dimensions and rust resistance, the offered Mineral Insulated Thermocouple is available at very reasonable rates.

Product details

|

Brand |

Customized |

|

Temperature Range |

Customized |

|

Product Type |

Thermocouple |

|

Model Name/Number |

Mineral Insulated Thermocouple |

|

Material |

Stainless Steel |

|

Power Source |

Electric |

|

Usage/Application |

Industrial |

Versatile Sensing for Industrial Applications

These MI thermocouples are designed for rigorous industrial temperature sensing tasks, thanks to their robust construction, various sheath diameters, and high-performance materials. They withstand harsh conditions, allowing for accurate thermal energy measurement and monitoring in diverse manufacturing environments, refineries, and process plants.

Precision Meets Durability

Our thermocouples adhere to international standards, delivering Class 1 accuracy (up to 1.5C) and rapid response (3 seconds). Their insulation resistance over 1000 M and quality sheath materials (SS304, SS316, Inconel 600) ensure consistent, reliable readings, even in challenging environments or at high process temperatures.

FAQs of Mineral Insulated Thermocouple:

Q: How is a mineral insulated thermocouple installed in industrial applications?

A: Mineral insulated thermocouples can be mounted as probe/immersion, surface, or custom mount types. Installation depends on process requirements; typically, the sensor is inserted into a thermowell or directly into the process medium, ensuring the minimum bend radius of 2x sheath diameter is maintained to avoid damage.Q: What are the benefits of using mineral insulated thermocouples for temperature measurement?

A: MI thermocouples offer fast response times (3 seconds), robust mechanical strength, flexibility in mounting, and high insulation resistance. Their design allows accurate and reliable temperature readings in demanding environments, minimizing downtime and enhancing process control.Q: When should I choose SS304, SS316, or Inconel 600 sheath material for a thermocouple?

A: The choice of sheath material depends on your process environment. SS304 suits general industrial conditions, SS316 offers enhanced corrosion resistance, and Inconel 600 is ideal for high-temperature or highly corrosive settings. Material selection ensures sensor longevity and measurement reliability.Q: Where can mineral insulated thermocouples be used?

A: These thermocouples are widely used in manufacturing, petrochemical plants, power generation, pharmaceuticals, and research laboratories across India. Their robust construction allows installation in both harsh and standard environments for continuous temperature monitoring.Q: What process ensures high insulation resistance in MI thermocouples?

A: The mineral insulation, typically compacted magnesium oxide (MgO), is tightly packed around the thermocouple wires inside the sheath. This design provides reliable insulation, resulting in resistance greater than 1000 M at 500V DC at room temperature, ensuring measurement integrity.Q: How does an MI thermocouple function as a passive device?

A: MI thermocouples generate a voltage proportional to the temperature difference between the measuring and reference junctions. As passive sensors, they do not require external power; they interface directly with indicators, controllers, or transmitters for temperature readout.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Temperature Sensors Category

Mineral Insulated Thermocouple

Minimum Order Quantity : As per Requirement Unit

Usage : MI Thermocouples are very tough and can withstand up to 1250C (depending on design and thermocouple type) making them perfect for a wide variety of industrial uses such as ovens, kilns and furnaces

Function : The standard plug enables the temperature sensor to be easily connected and disconnected to a variety of controllers and readouts in busy and demanding environments.

Product Type : Insulated Thermocouple

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free