Thermocouple Cables

Thermocouple Cables Specification

- Conductor Shape

- Round

- Tensile Strength

- Above 500N (depends on exact construction)

- Number of Conductor

- 2 (for single pair) or as specified

- Diameter

- Varies (typical range: 2mm to 8mm depending on cores and insulation)

- Cable Type

- Thermocouple Cable (Extension or Compensating)

- Rated Temperature

- Up to 260C (higher options available based on insulation)

- Dielectiric Strength

- Min. 2kV for 1 minute

- Locking Type

- Standard thermocouple connector compatible

- Impedance

- Typically < 10 /km

- Insulation

- PTFE/PVC/Fiberglass

- Features

- High accuracy, flexible construction, durable, suitable for harsh environments

- Conductor Type

- Solid or Stranded

- Install Type

- Fixed or flexible installation

- Product Type

- Thermocouple Extension & Compensating Cable

- Length

- Available in standard and custom lengths (1m, 5m, 10m, 50m, 100m, etc.)

- Voltage

- Rated up to 300V

- Insulation Material

- PTFE/PVC/Fiberglass

- Application

- Temperature measurement, process control, industrial and laboratory use

- Jacket Material

- PVC, PTFE, or Fiberglass

- Connector Color

- Various (typically yellow, green, or blue for identification)

- Jacket Color

- Generally available in white, yellow, or green

- Dimension (L*W*H)

- Custom as per cable size and requirement

- Color

- White, Yellow, Green, or as requested

- Material

- PVC, PTFE, Fiberglass (as per construction)

- Size

- Customizable (commonly 0.5mm to 2.5mm)

- Flame Retardancy

- Yes, as per insulation type

- Thermocouple Types Supported

- K, J, T, E, N, R, S, B

- Packaging Type

- Rolls, Reels, or Carton Boxes

- Outgassing Property

- Low outgassing (on Teflon/Glass cables)

- UV Resistance

- Available on PTFE and certain PVC jackets

- Halogen Free Option

- Available on request

- Maximum Conductor Resistance

- Depends on conductor and size, e.g., <34 Ohm/km for 0.5mm²

- Minimum Bend Radius

- 10 x cable diameter

- Insulation Thickness

- Typically 0.4mm to 0.8mm (can vary as specified)

- Standards Compliance

- ANSI, IEC, BS, DIN

- Twisted Pair Option

- Available for noise immunity

- Oil & Chemical Resistance

- Available with PTFE and special insulations

- RoHS Compliance

- Yes

About Thermocouple Cables

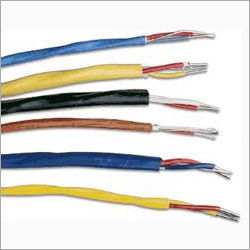

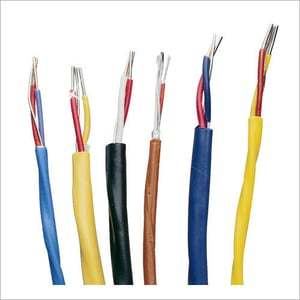

We are recognized as the prominent manufacturer and exporter of a wide assortment of Thermocouple Cables that is available in various thicknesses and colors in order to meet the diverse needs of the clients. Offered cables are manufactured using supreme grade raw materials and advanced machinery as per the set industry norms. Offered Thermocouple Cables are highly appreciated for their high tensile strength, durability, fine finish and cost effectiveness.

Product details

| Thermocouple Type | J,K,T, R, S Type |

| Size | Customized |

| Length | Customized |

| Material | Customized |

| Brand | Customized |

| Color | Black,Red,Blue,Silver |

| Conductor Type | Copper & Constantan ,Solid |

Accurate Measurement with Robust Construction

Designed for high-precision temperature monitoring, these thermocouple cables ensure reliable data integrity even under demanding conditions. Their robust construction and compliance with international standards make them ideal for process control in industrial and laboratory applications. Flexible and durable, they easily withstand mechanical stress while delivering consistent results.

Versatile Options and Noise Immunity

A broad selection of thermocouple types, insulation materials, and conductor designs is available, including twisted pairs for enhanced noise immunity. Choose from halogen-free or low outgassing forms for sensitive environments. Various packaging, color coding, and connector options support seamless identification and installation.

Built for Challenging Environments

Engineered with flame-retardant, oil-resistant, and UV-protected insulations, these cables operate reliably in harsh surroundings. Rated for temperatures up to 260C (with higher options upon request) and voltages up to 300V, they maintain performance in both fixed and flexible installations. High tensile strength and flexible construction support a wide range of industrial uses.

FAQs of Thermocouple Cables:

Q: What thermocouple types do these cables support?

A: These cables are compatible with all major thermocouple types including K, J, T, E, N, R, S, and B, making them suitable for diverse temperature measurement and process control applications.Q: How do I choose the right insulation material for my application?

A: Selection depends on your operating environment. PTFE insulation offers superior chemical, oil, and UV resistance, while fiberglass withstands high temperatures. PVC is commonly used for cost-effective, general-purpose needs. Each material is available to suit different temperature ratings and environmental demands.Q: When should I use twisted pair thermocouple cables?

A: Twisted pair designs should be used in electrically noisy environments where signal integrity is critical. Twisting helps minimize electromagnetic interference, ensuring accurate temperature readings in industrial settings.Q: Where can these thermocouple cables be installed?

A: They are ideal for both fixed and flexible installations in industrial plants, laboratories, process control systems, and outdoor applications. The cables durability and weather resistance allow them to perform reliably in harsh conditions.Q: What process ensures the flame retardancy and chemical resistance of these cables?

A: Flame retardancy and chemical resistance are achieved through specialized insulation materials such as PTFE and certain PVC compounds, chosen according to required standards. These materials are tested under stringent conditions to meet regulatory and safety standards.Q: What are the length and packaging options available?

A: Cables are offered in standard rolls, reels, or carton boxes, with custom lengths ranging from 1m to 100m and beyond. This enables convenient transport, storage, and integration into existing systems.Q: What are the benefits of using these thermocouple cables in harsh environments?

A: Their high accuracy, flexibility, flame retardancy, and resistance to oil, chemicals, and UV make them reliable in demanding settings, ensuring long service life and consistent temperature measurements even under extreme conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thermocouple Cables Category

Thermocouple Compensating Cable

Usage : Industry

Material : Rubber, Copper

Size : Customized

Protecting Tube Material : Rubber

Product Type : Compensating Cable

Wire Length : Customized Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS